Towards the start of the AU 2025 semester, I decided that I wanted to work on something that would test my 3d design work along with my electrical engineering skills. Inspired by BPS.space, Garrett R, Jacob Thornhill, and various others, I decided I wanted to build a Thrust Vector Control (TVC) Model Rocket.

For those that don't know, a thrust vector contol rocket is a rocket that uses a gimbaling motor mount for stability. This is different than the traditional method of aerodynamic stability which leverages fins near the base of the rocket to provide stability. For the purposes of model rocketry, this allows the rocket to maintain an upright position while flying at very low speeds.

Instead of jumping straight into making a full rocket, I decided to take it slow by starting out with the motor mount. This would give me the opportunity to rapidly iterrate on a small scale without having to overly commit to any large changes.

I started by creating a small list of goals that I had for the mount.

- Fit within a 4 inch tube

- 15 degree range of motion

- Use MG995 servos (These were the servos I had already used in a previous project, and I had 2 extra)

- Fully 3d printed

- Get it to work

Goals for a Thrus Vector Control Mount

Some of these goals had better reasoning behind them than others, but I figured it would work no matter what

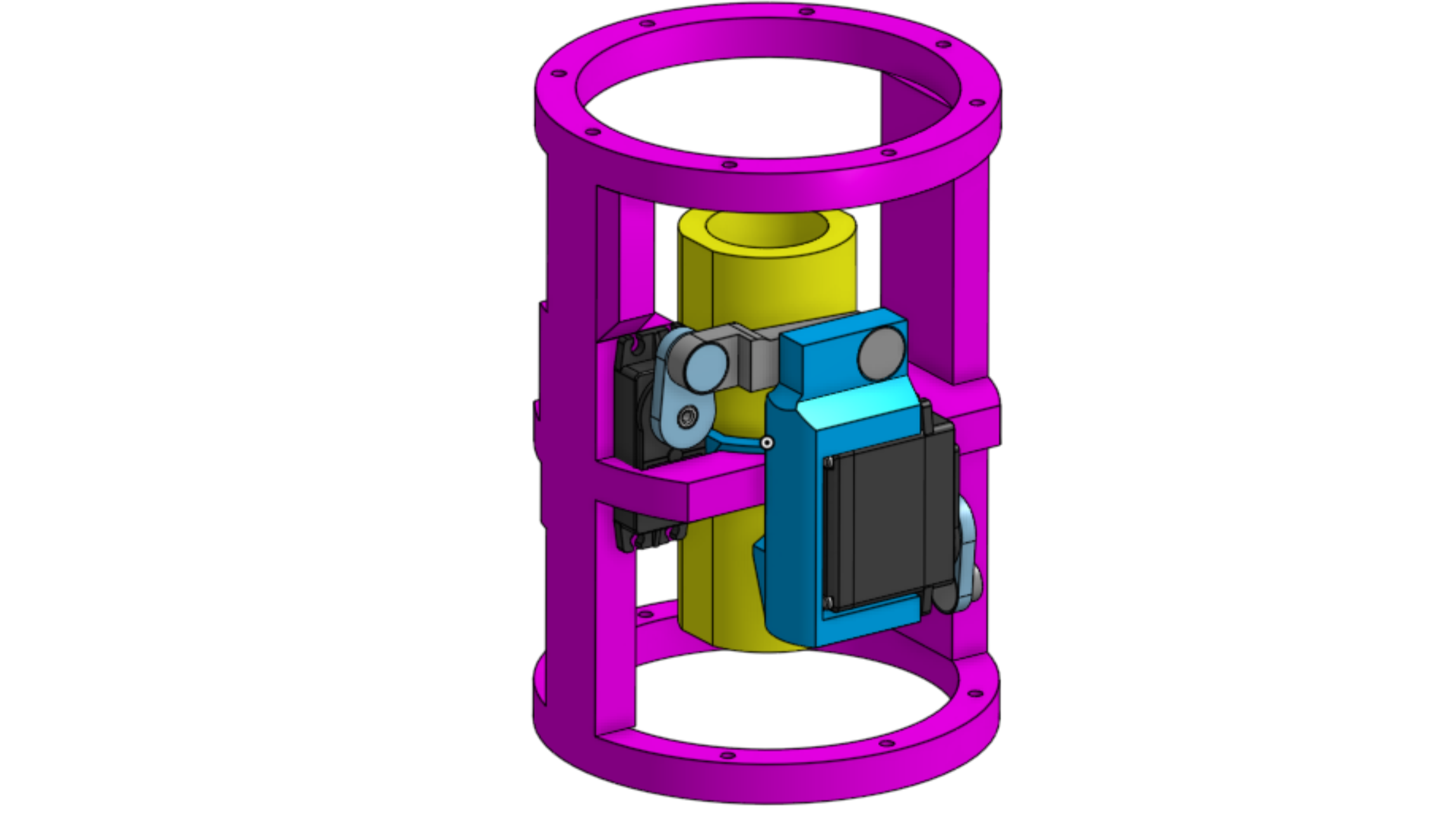

With my goals for the project defined, I hopped straight into the CAD work. Within about a week, I had a rough mockup assembly that worked in the perfect world of CAD. Unfortunately but as I had planned, things didn't go as well once I began printing out the pieces.

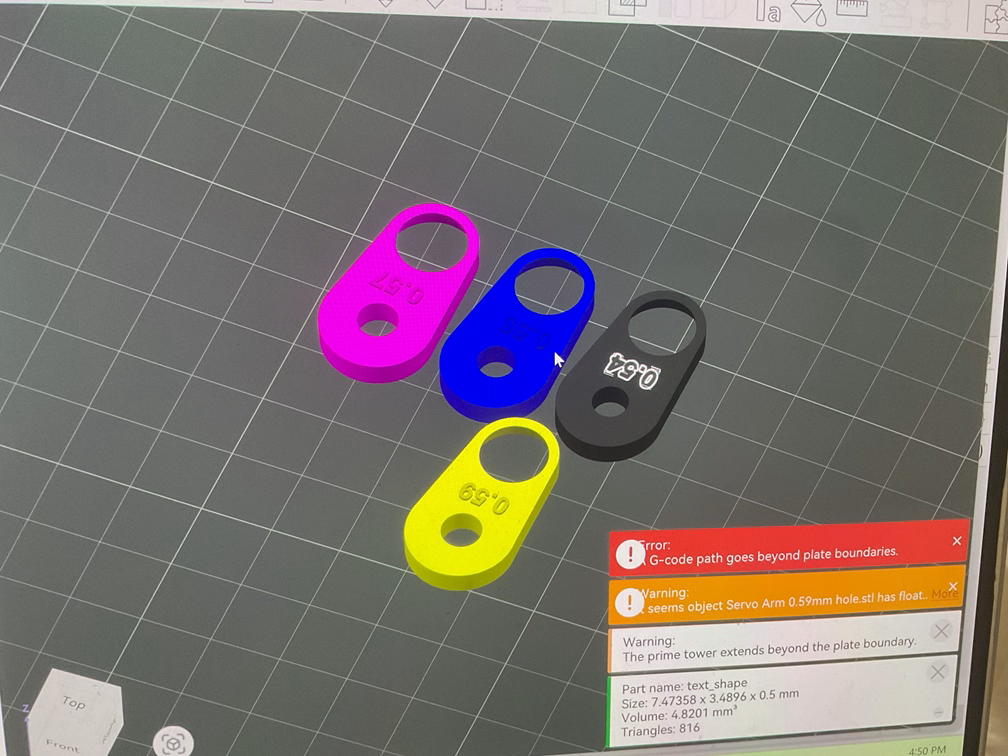

Some of the parts were too small, while others were to lose. The 3d printed plastic hinges I had designed were too small, and broke with just a small amount of normal force. The 3d printed servo horns wouldn't fit on the mount. It was a bit of a mess. Slowly, I went through each mistake. I printed a couple test prints in order to figure out what types of tolerences would be needed.

Eventually, I was able to get everything to fit together well enough to hook the motor mount up to a single servo motor. This was super exciting as I got to see the theoretical motor gimbal for the first time.

Riding the success of the last test, I adjusted the outer ring so that it would be able to sit flat on a table. I also added some screw holes so that I can securely attach the mount to a test stand. With this new print, I was able to wire up the motor mount to an ESP32. The ESP32 enabled me to control the direction of the motor vector with a PlayStation 3 controller. While this was a cool demo to show my friends, I don't have the reflexes to actully steer. So I'm going to leave this project here for now, while I work on a method of stabilization using a microcontroller.

- Test fire this iteration of the mount

- Figure out how to balance the rocket using an Inertial Measurement Unit (IMU)

- Design an alternative to plastic hinges